4.1. INTRODUCTION

The experimental investigations have been done to check the qualities of the recycled materials from the construction and demolition waste. The Chapter contains the experimental results of the recycled materials (Recycled Coarse Aggregates & Recycled Fine Aggregates) and of some products made by these recycled materials (Different Concrete blocks). Also the comparison of the characteristics of the recycled materials and that of standard materials have been included for the suitability of the Recycled materials in Real Environment/Construction Industries.

The following laboratory tests have been done on the different materials containing recycled aggregates: -

a) Compressive Strength test of the eco-concrete

b) Compressive Strength test of the cement mortar cubes

c) Compressive Strength test of the Concrete Bricks

d) Laboratory Tests on the Recycled Coarse Aggregates

i. Specific Gravity Test and Water Absorption Test

ii. Aggregate Impact Test

iii. Bulk Density, Fineness Modulus Test (FM)

On the basis of the results obtained from laboratory test. It has been decided that where it can be used in construction work. Use of the all the recycled materials have been explained in the next chapter.

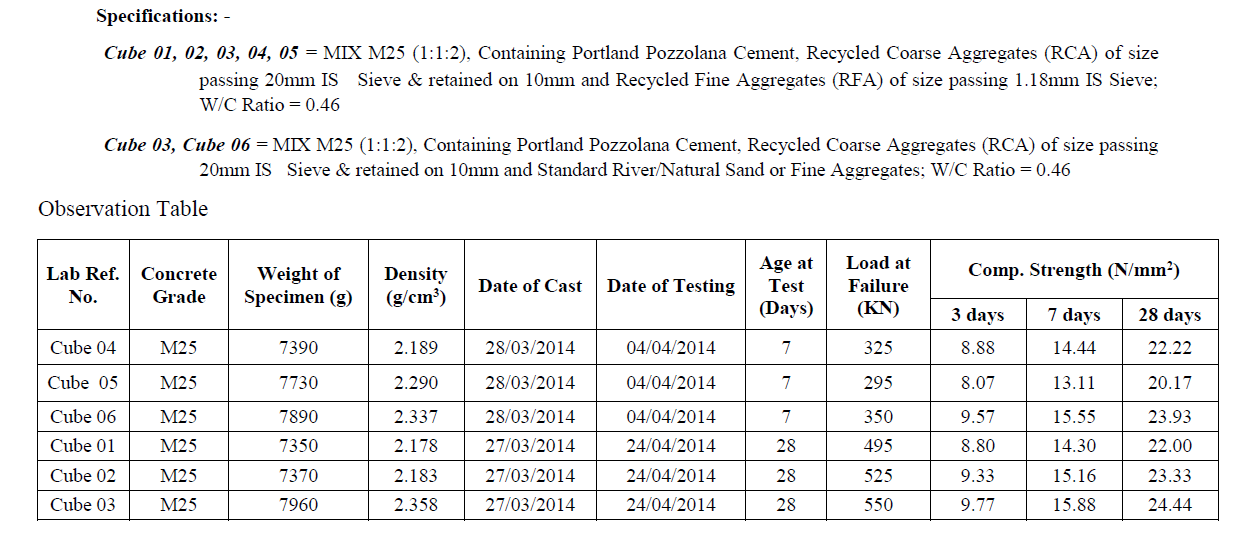

4.2. Compressive Strength Testing of Eco-Concrete

Out of many test applied to the concrete, this is the utmost important which gives an idea about all the characteristics of concrete. By this single test one judge that whether Concreting has been done properly or not. The concrete cube size used under this project was 15cm x 15cm x 15cm as we have used recycled coarse aggregates of the size 10mm-20mm. These specimens are tested by compression testing machine after 7 days curing or 28 days curing. Load should be applied gradually at the rate of 140 kg/cm2 per minute till the Specimens fails. Load at the failure divided by area of specimen gives the compressive strength of concrete. (As per IS: 516)

APPARATUS: - Compression testing machine, cube mould of size 15cmx15cm x15cm, temping rod, vibrator, others.

PREPARATION OF CUBE SPECIMENS: - The proportion and material for making these test specimens have been done as per code IS: 516.

SPECIMEN: - 6 cubes of 15 cm size Mix. M25

HAND MIXING

a) Mix the cement and fine aggregate on a water tight none-absorbent platform until the mixture is thoroughly blended and is of uniform color

b) Add the coarse aggregate and mix with cement and fine aggregate until the coarse aggregate is uniformly distributed throughout the batch

c) Add water and mix it until the concrete appears to be homogeneous and of the desired consistency.

SAMPLING

a) Clean the mounds and apply oil

b) Fill the concrete in the molds in layers approximately 5cm thick

c) Compact each layer with not less than 35strokes per layer using a tamping rod (steel bar 16mm diameter and 60cm long, bullet pointed at lower end.

d) Level the top surface and smoothen it with a trowel. CURING The test specimens are stored in moist air for 24hours and after this period the specimens are marked and removed from the molds and kept submerged in clear fresh water until taken out prior to test.

PROCEDURE

a) Remove the specimen from water after specified curing time and wipe out excess water from the surface.

b) Take the dimension of the specimen to the nearest 0.2m

c) Clean the bearing surface of the testing machine

d) Place the specimen in the machine in such a manner that the load shall be applied to the opposite sides of the cube cast.

e) Align the specimen centrally on the base plate of the machine.

f) Rotate the movable portion gently by hand so that it touches the top surface of the specimen.

g) Apply the load gradually without shock and continuously at the rate of 140kg/cm2/minute till the specimen fails

h) Record the maximum load and note any unusual features in the type of failure.

CALCULATIONS

Size of the cube =15cm x15cm x 15cm

Weight of the Specimen (Kg) = W Kg

Area of the specimen = 225cm2

Compressive strength (fck) at 7 days or 28 days = Load/Cross Section Area of cube (N/mm2)

RESULT

Average compressive strength of the concrete cube =13.775 N/ mm2 (at 7 days)

Average compressive strength of the concrete cube = 22.665 N/mm2 (at 28 days)

Percentage strength of concrete at various ages:

The strength of concrete increases with age. Table shows the strength of concrete at different ages in comparison with the strength at 28 days after casting.

Compressive strength of different grades of concrete at 7 and 28 days:

CONCLUSION OF THE TEST

As per the result obtained, we can conclude that the recycled coarse aggregates can be used widely in the construction industry for the construction works including both Plain cement concrete work and reinforced cement concrete works as well. The another benefit is that the Recycled fine aggregates (less than 1.18mm size) can be used in place of the natural sand in concrete for the plain cement concrete along with recycled coarse aggregates.

(This chapter is continue...)

Hi Sir/Madam,

ReplyDeletePercentage strength of concrete at various ages table can be found in which British Standard?

Thanks in advance.

Jost’s material handling provides innovative solutions for internal material handling needs for its customers so that it improves the efficiencies of their processes.

ReplyDeleteShock Testing Machines of various capacities to be used in the design and destructive testing of components, hybrids, circuits, and complete assemblies. These machines are used testing a variety of products from Aerospace, Millitary, Industrial and consumer

Shock Testing Machines